Rutherford Appleton Laboratories

The new Research Complex at Harwell Oxford is a multidisciplinary laboratory providing world leading facilities for new and cutting edge research in both life and physical sciences and the interface between them.

Environmental issues were at the forefront of the building design with all energy use carefully monitored. An innovative Earth Tube has been buried along side the building to utilise the relatively stable below ground temperature, heating the building’s incoming air in the winter and cooling during the summer.

CPS were contracted to design and manufacture six thermoplastic heat exchangers complete with spray cleaning systems as part of the building’s heat recovery system.

The units are designed for extraction flow rates of 17,172 m3/hr and 20,196 m3/hr, manufactured from polyethylene with polypropylene housings. The units have minimum design life of 20 years.

Initial results for the systems are as follows:

Air inlet Temperature prior to heat recovery system : 8.5 °C

Air Temperature after heat recovery System: 14.2 °C

Air Temperature into Laboratories: 18 °C

Extract air temperature: 21 °C

Gallery

Rutherford Appleton Laboratories

The new Research Complex at Harwell Oxford is a multidisciplinary laboratory providing world leading facilities for new and cutting edge research in both life and physical sciences and the interface between them.

Environmental issues were at the forefront of the building design with all energy use carefully monitored. An innovative Earth Tube has been buried along side the building to utilise the relatively stable below ground temperature, heating the building’s incoming air in the winter and cooling during the summer.

CPS were contracted to design and manufacture six thermoplastic heat exchangers complete with spray cleaning systems as part of the building’s heat recovery system.

The units are designed for extraction flow rates of 17,172 m3/hr and 20,196 m3/hr, manufactured from polyethylene with polypropylene housings. The units have minimum design life of 20 years.

Initial results for the systems are as follows:

Air inlet Temperature prior to heat recovery system : 8.5 °C

Air Temperature after heat recovery System: 14.2 °C

Air Temperature into Laboratories: 18 °C

Extract air temperature: 21 °C

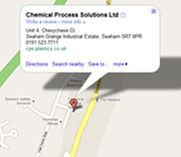

Contact Details

Chemical Process Solutions Ltd,

Unit 4,

Chevychase Court,

Seaham Grange Ind Est,

Seaham,

County Durham,

SR7 0PR

t: 0191 523 7711

f: 0191 523 7733

0191 523 7711

0191 523 7711